To ensure the best possible delivered gas quality. Automated facilities, Certified & Accredited Labs, Gas purification & Raw material selection, Cylinder selection & treatment, Personnel recruitment & training -Sales

To ensure the best possible delivered gas quality. Automated facilities, Certified & Accredited Labs, Gas purification & Raw material selection, Cylinder selection & treatment, Personnel recruitment & training -Sales

To demonstrate total data transparency to customers

Take advantage of new opportunities as quickly as possible & adapt to the requirements.

Local stock or special shipment according to customer expectation

Associated delivery systems (Regulators, Gas Distribution – Industrial and Specialized ) are as critical as the gas quality supplied

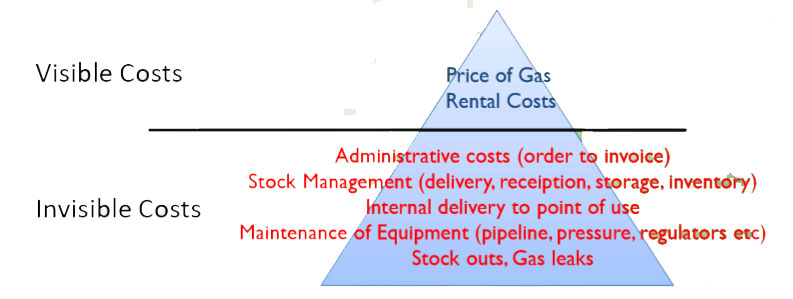

The smallest errors can lead to expensive reworking or lost time incidents

From order by fax to the responsibility of supply transferred to customer, -- Internal Delivery to Point of Use --Contnuity of Supply

Maintenance of pipeline & equipments, spare parts, manpower, travelling costs

Consumption analysis (flow, pressure, 1st level leak detection, distribution qty)

Implementing Safety practices, Limited authorised user access to store, Cylinder identification

User identification

Levels of control

On customer site or from Supplier to Customer site

AGEM'slocal representative and unique interface with the Customer. In charge of business development and the offer enlargement.

High Pressure Packaging Low Pressure Packaging Bulk Packaging

© Agem - All right reserved.