Air Gas Electronic Materials (AGEM) is a major supplier of Sulphur Hexafluoride (SF6) to the Electronic and Semiconductor, Power, R&D and Institute.

AGEM supplies various purity of SF6 with grade ranging to Circuit breaker, Gas Insulated substation, Electric, laser, chemical, military, space aviation, physical research and electronic & semiconductor applications and as per the industrial requirements.

AGEM can offer the process of purification crude SF6 or recycled SF6 from 99% (2N grade) to 99.9999% (6N grade) based on customer requirements.

We have an advanced solution to meet the difficulties in stock pile up of used SF6 over the time. It includes the benefits as mentioned below:

A colorless, odorless, non-flammable, non-reactive, non-toxic gas.

Excellent thermal stability, does not decompose at temperatures above 500°C in pure form. It has excellent electrical insulation and arc extinguishing properties, and insulation capacity is 2.5 times more than Air & Nitrogen. Useful in Synthetic / Analytical chemistry.

Component |

Grade Purity |

Grade - I 99.995% |

Grade - II 99.999% |

N2 |

20 |

2 |

|

O2 + Ar |

10 |

1 |

|

CO |

1 |

0.1 |

|

CO2 |

1 |

0.1 |

|

CF4 |

10 |

0.5 |

|

Acidity (HF) |

0.1 |

0.3 |

|

Moisture (H2O) |

2 |

0.5 |

|

Mineral Oil |

5 |

- |

|

THC |

- |

0.3 |

Grade |

Packaging Specifications |

||

Cylinder Size (WC) |

Fill Content (Kg) |

Standard Valve |

|

Grade – I |

3 |

1 kg to 3.75kg |

CGA 590 |

6.8 |

4 kg to 8.5kg |

CGA 590 |

|

10 |

9kg to 12.5 kg |

CGA 590 |

|

15 |

13kg to 19kg |

CGA 590 |

|

24 |

20kg to 30kg |

CGA 590 |

|

40 |

30kg to 50 kg |

CGA 590 |

|

47 |

50kg to 58 kg |

CGA 590 |

|

Certificate of Analysis Included. Individual or batch Certificate of Analysis available on request. |

|||

Grade – II |

3 |

3 |

CGA 590 |

10 |

11 |

CGA 590 |

|

24 |

25 |

CGA 590 |

|

40 |

50 |

CGA 590 |

|

47 |

50 |

CGA 590 |

|

Certificate of Analysis Included. Individual or batch Certificate of Analysis available on request. |

|||

Molecular Weight |

146.055 g/mole |

Specific Volume |

2.65 cf/lb @ 70°F & 1 ATM |

Flammability Limits |

Non-flammable |

Melting Point |

-50.8°C (-59.4°F) |

Critical Temperature |

45.5°C (113.9°F) |

Gas Density |

0.3847 lb/ft3 |

Sulphur hexafluoride (SF6) is an excellent dielectric gas for high voltage applications. It is chemically inert, gaseous even at low temperature, non flammable, non toxic, non corrosive. Its combined chemical, thermal and electrical properties allow many advantages to be achieved.

SF6 allows simplified design of high and medium voltage switchgears because of size and weight reduction, quiet and reliable handling and maintenance. Outstanding properties are its dielectric strength and dielectric constant unchanged from a few Hz up to several GHz, and such as arc quenching properties to prevent arc from occurring while its molecular fragments rapidly recombine after the source of arc is removed. Furthermore the high molar heat capacity and low viscosity enables it to transfer heat very effectively.

SF6 is used in several non-electric and electronic applications. Processes have been developed for magnesium casting in which a protective atmosphere of SF6 based gas mixture prevent the formation of undesirable byproducts. Other foundry applications are those employing N2/SF6 mixtures in aluminum casting as refining and degassing agents.

SF6 is also used in the semi-conductor industry, as etching gases for plasma etching or as cleaning gases to clean the chambers after the etching process.

Several minor applications are regarding leak detection, tracer gas studies, loud speakers and lasers.

The IEC (International Electrotechnical Commission) has several SF6 standards in place including:

SF6 has been proven as an excellent material for high voltage insulation, it and has been widely used in this applications for decades.

However, it has extremely high global warming potential (GWP) which is almost the worst material among the chemicals known today.

More and more countries are trying to reduce the usage of SF6 or to phase out this material in the field applications. However, the alternative materials are either not economically practical or poor performance.

The customers who is using it for insulation applications are facing big issues of dealing the used SF6.

Air Gas Electronic Materials Enterprise Co., Ltd (AGEM) is currently purifying SF6 and supplied to the electronic customers covering semiconductor, TFT-LCD (flat panel) etc.

AGEM is supplying SF6 with different grades such as 4N-4N5 for power grid applications and 5N-6N for electronic applications.

We are capable to purify the crude SF6 or recycled SF6 from 99% (2N) to 99.9999% (6N) depending on the customer requirements.

We are also supplying the virgin SF6 to our customers in all of industrial sectors.

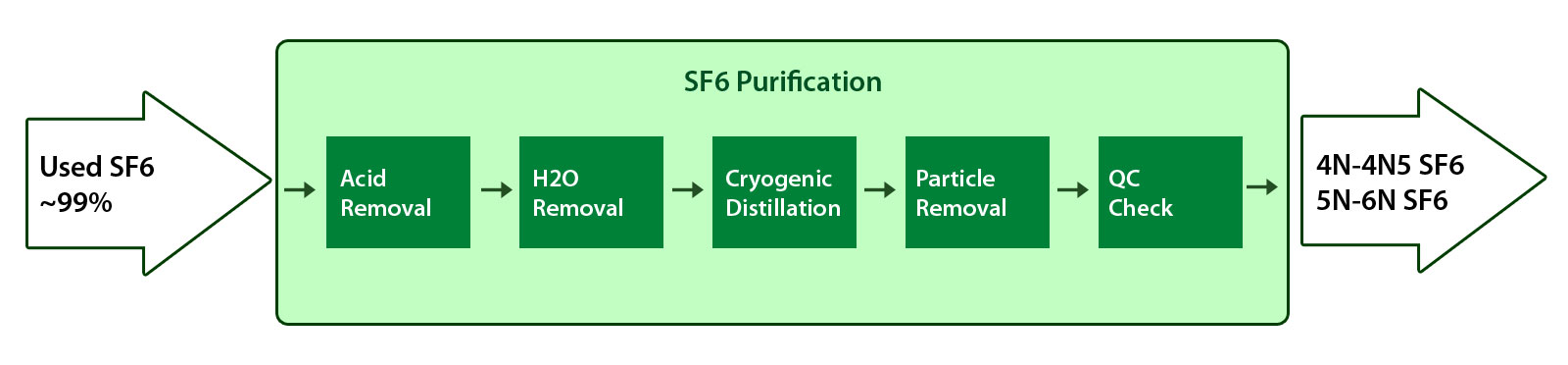

The used SF6 is subjected to our purification system. Acid components which were generated by S-F bond dissociation during its service period are removed first. Moreover, acid-free SF6 is dried below 5ppm H2O content in order to prevent clocking the cryogenic purification system. The dried SF6 is going through the cryogenic purification system which removes H2, N2, O2, CO, CO2, and other unwanted impurities in the stream, purified SF6 is finally passed through the particle filter to remove the particles which were introduced in its service journey and purified particle-free SF6 will pass a series of QC to make sure it meets all specification requirements which totally complied with IEC SF6 standard.

High Pressure Packaging Low Pressure Packaging Bulk Packaging

© Agem - All right reserved.

Designed by Mirackle Solutions